A Global Leader in Plastics Manufacturing

The Plastek Group is a global leader in plastics manufacturing, offering decades of experience in plastic molding services and packaging assembly. We embrace innovation and use advanced techniques and technologies to create clients’ unique package and mold designs, and assemble reliable product packaging for export.

Our Plastic Injection Molding Services

Create complex and unique plastic packaging with our expert injection molding facilities. We complete high-volume orders and offer custom plastic molding using injection and injection stretch molding for new and standard designs. Our dedicated and state-of-the-art injection molding machines include:

- Multi-shot machines 90 tons – 950 tons.

- Chilled water system to cool molds.

- Multiple robots for part removal.

- High-cavitation, single-face, and stack molds.

- All-electric molding machines.

- High-performance molding machines.

- Latest hot runner technology for faster cycles and low waste.

Our plastic mold manufacturing team specializes in high-density polyethylene (HDPE), and polypropylene (PP) materials but can also fulfill custom injection molding orders for diverse plastic resin types, including low-density polyethylene (LDPE), polyethylene (PE), and post-consumer resin (PCR).

Blow Molding Products We Manufacture

Plastek has extensive experience in blow molding containers and bottles for pharmaceutical, cosmetics, and other industries. We use advanced systems and our decades-long expertise to create plastic products of various sizes, shapes, and plastics. You can order various blow-molded plastic products such as:

- Vials.

- Bottles.

- Jars.

- Barrels.

- Containers.

- Buckets.

- Spray bottles.

- Squeeze tubes.

Blow molding presses range from 15 to 85 tons, enabling technicians to create plastics of diverse sizes. We have heavy machines dedicated to improving precision and driving high-power production and efficiency.

Assembly

Plastek’s experience assembling plastic packaging is second to none in the industry. We can provide high-volume, multiple-component assembly in a variety of shapes and sizes. Our assembly sequences promote efficiency, and accuracy, and render quality, and secure products. The Plastek aim is to create exceptional, durable packaging using:

- High-speed assembly.

- 100% auto inspections at lines.

- Hot glue assembly.

- Sonic welding assembly.

- Assembly robots.

- End-of-arm-tooling (EOAT).

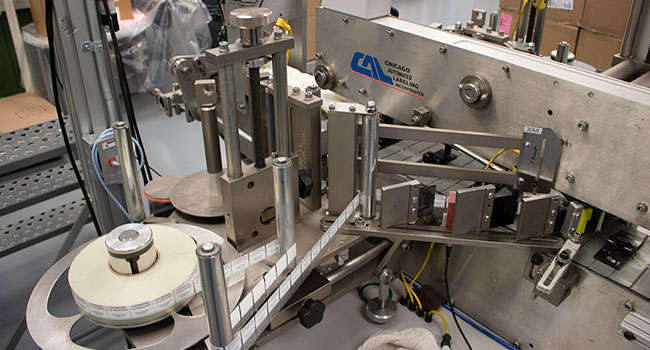

Decorating

Give your final packaging a branded touch with our decorating solutions. Plastek can manage your product decorating needs with the same attention to quality that surrounds every service that we provide. Final-step decorating services we offer include:

- Pressure sensitive labeling.

- Silkscreen decorating.

- Hot stamping.

- Foil seal lining.

- Pad printing.

- High-speed label wrapping.

Cell Manufacturing

- Improved material flow

- Reduces setup time

- Increases efficiency

- Automation of machines, robots, conveyers, & packaging machines