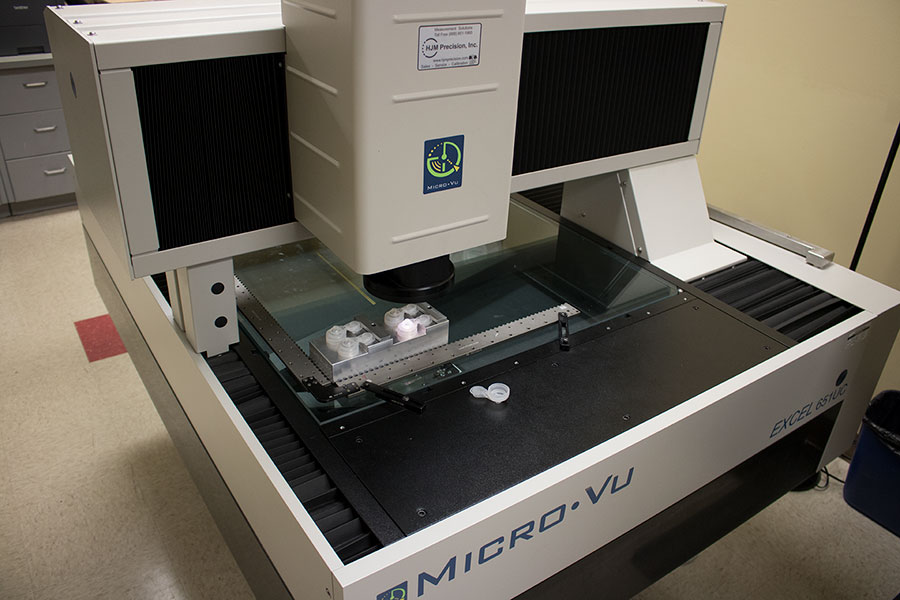

First Article

At Plastek, we go to great lengths to ensure the high-cavitation molds and other products we create for our customers deliver the expected outcomes. We have developed a comprehensive First Article Process to ensure our production processes and methods create an acceptable item.

Our process encompasses a thorough review of all applicable documents, including drawings, purchase orders, and engineering specs. This information provides irrefutable evidence that all procedures are validated, understood, and verified.

Specific examples of what our First Article Process entails include a review of dimensional characteristics, such as size, shape, and feature locations. It can also involve various inspection and testing steps to verify the findings and provide more certainty.

Statement for First Article

Clear, effective communication is essential to ensure the success of the First Article Process and every other mold design and manufacturing aspect. It’s also necessary when establishing positive, enduring relationships with our customers.

Our First Article department makes every effort to keep the lines of communication open from start to finish. We also extend these lines to other areas of our company to ensure the satisfactory development of your project specifications during every phase. You’ll have direct access to a dedicated customer service representative and project manager, as well as our R&D team, tooling and engineering department, designers, and other critical personnel.

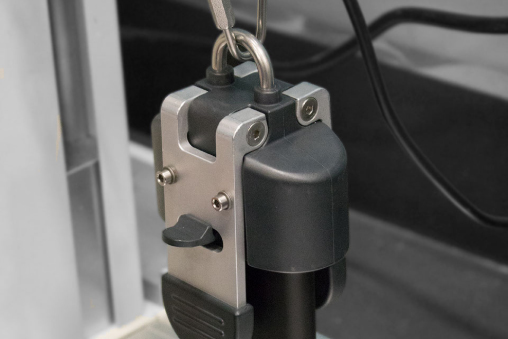

Tests Performed:

Comprehensive testing is a crucial component of our First Article Process when verifying the results. Examples of the First Article tests we conduct cover all the essential aspects that impact product quality, performance, and durability:

- Air flow

- Leakage

- Torque

- Strength

- Vacuum

- Breakage

- Destructive

- Application and removal forces